In a groundbreaking advancement that could redefine spacecraft manufacturing, the Indian Space Research Organisation (ISRO) has successfully tested a 3D-printed liquid rocket engine. This achievement not only signifies a leap in rocket engineering but also paves the way for more sustainable and efficient space travel technologies.

The Rise of 3D Printing in Aerospace

Innovative Design and Manufacturing

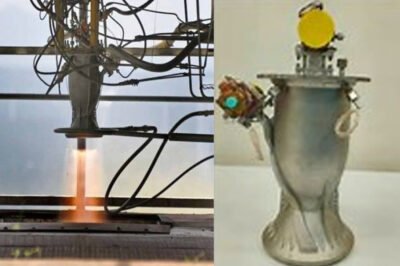

The successful test of the PS4 engine, integral to the Polar Satellite Launch Vehicle (PSLV), marks a significant milestone. Using advanced Additive Manufacturing (AM) techniques, this engine was produced with a fraction of the traditional raw materials and in much less time, showcasing the potential of 3D printing in enhancing production efficiency.

Material Efficiency and Reduction

The engine required only 13.7 kg of metal powder, compared to 565 kg needed for conventional processes. This drastic reduction in material use not only cuts costs but also aligns with sustainable manufacturing practices, reducing the environmental footprint of rocket production.

Extended Test Success

Conducted at the ISRO Propulsion Complex in Mahendragiri, Tamil Nadu, the test ran for 665 seconds, validating the performance and reliability of the 3D-printed engine under simulated flight conditions. This test is a testament to the durability and functionality of components produced via AM technology.

Technological and Economic Implications

Reduced Complexity and Enhanced Reliability

The new manufacturing method has simplified the engine’s design, reducing the number of parts from 14 to just one and eliminating 19 weld joints. This not only minimizes potential points of failure but also significantly enhances the engine’s structural integrity.

Future Prospects and Challenges

While the success of this test opens up numerous possibilities, it also sets the stage for further research and development. ISRO’s breakthrough could lead to more widespread adoption of AM technology in building complex, high-performance space machinery.

Conclusion

ISRO’s successful integration of 3D printing technology into rocket engine production marks a pivotal moment in space exploration. As this technology continues to evolve, it could lead to more innovative, cost-effective, and environmentally friendly approaches to constructing spacecraft and other aerospace components. With this achievement, ISRO not only propels India to the forefront of space technology innovation but also significantly contributes to the global shift towards more sustainable aerospace engineering practices.

Leave a Reply