The Indian Space Research Organisation (ISRO) has made a significant advancement in rocket technology with the development of a new lightweight Carbon-Carbon (C-C) nozzle for rocket engines. This innovation, crafted by the Vikram Sarabhai Space Centre (VSSC), aims to boost the efficiency and payload capacity of launch vehicles. But will this new technology truly transform rocket launches as we know them?

Introduction to ISRO’s Innovation

ISRO’s latest breakthrough involves the use of Carbon-Carbon composites to create a highly efficient nozzle divergent. This new development is not only lighter but also stronger and more durable under high temperatures than the materials currently used. Such advancements are crucial for enhancing the performance parameters of rocket engines, such as thrust levels and specific impulse, which in turn increase the payload capacity of rockets.

Advantages of the Carbon-Carbon Nozzle

Lightweight and Durable:

- Material Benefits: The C-C nozzle is made from advanced composite materials, which are known for their low density and high specific strength. This means the nozzle can withstand extreme conditions of space launches while being significantly lighter than traditional materials.

- Anti-Oxidation Coating: A special coating of Silicon Carbide on the nozzle helps protect against oxidation, further extending its operational life and reliability in the harsh environments of space.

Increased Payload Capacity:

- Enhancing PSLV’s Capabilities: The use of C-C nozzles is expected to reduce the mass of the nozzles in the PS4 stage of the Polar Satellite Launch Vehicle (PSLV) by 67%. This reduction could increase the payload capacity by up to 15 kg, a considerable gain for any space mission.

Testing and Future Applications

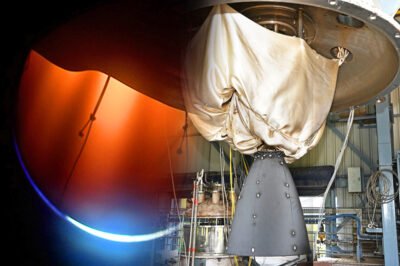

The new nozzle has undergone rigorous testing to ensure its performance under actual launch conditions. A 60-second hot test followed by a 200-second hot test were successfully completed, with the nozzle withstanding temperatures up to 1216K. These tests confirm the nozzle’s ability to perform as expected and pave the way for its future integration into operational launch vehicles.

Collaborative Efforts:

- Development and Testing: The development of the nozzle involved a collaborative effort between the Liquid Propulsion Systems Centre (LPSC) and the ISRO Propulsion Complex (IPRC), showcasing the expertise and integration of various ISRO facilities.

Conclusion

ISRO’s development of the Carbon-Carbon nozzle represents a pivotal step in the evolution of rocket technology. By reducing the weight and enhancing the durability of rocket nozzles, ISRO is not only improving the efficiency of its launch vehicles but also setting new standards in the space industry. As we look to the future, it is clear that innovations like these will play a crucial role in expanding our capabilities in space exploration.

Now, we invite you to weigh in: How do you think ISRO’s new Carbon-Carbon nozzle will impact the future of space launches? Share your thoughts and vote in our poll to express your opinion on this groundbreaking development.

Leave a Reply